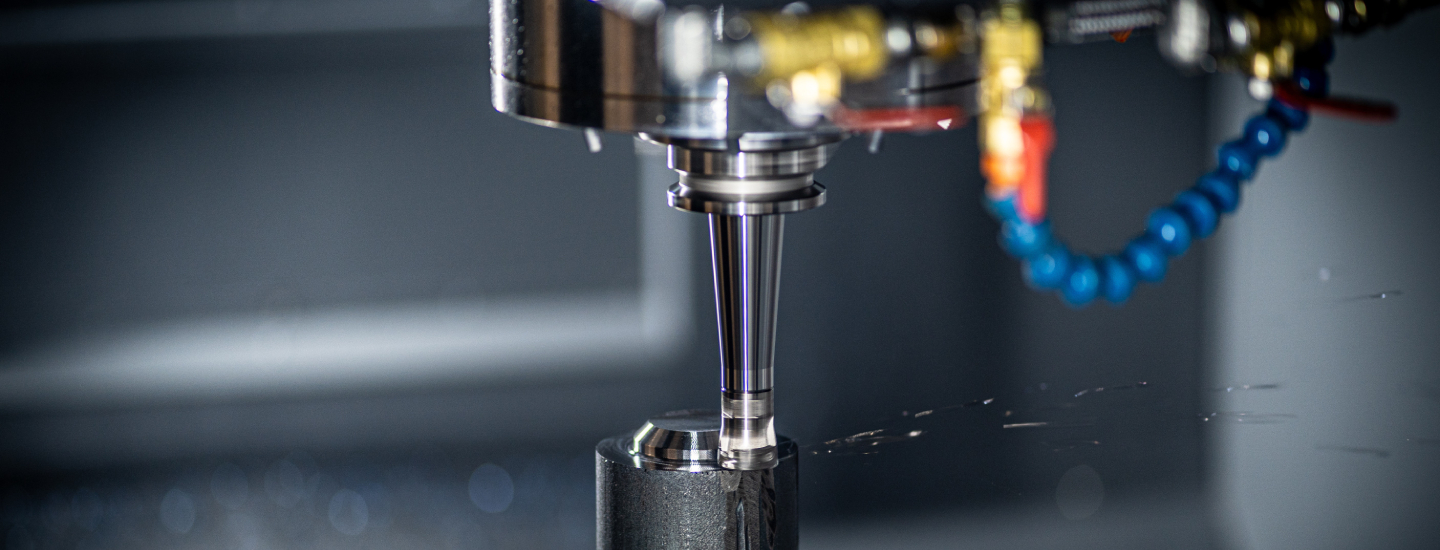

At Shree Umiya Enterprise, we deliver high-quality CNC machining solutions tailored to meet the diverse needs of industries worldwide. Equipped with cutting-edge technology and a skilled workforce, we ensure precision, reliability, and excellence in every component we produce.

Based in Gujarat, Shree Umiya Enterprise specializes in CNC machining services, offering end-to-end manufacturing solutions for industries ranging from automotive to aerospace. With decades of experience, we combine advanced machinery, rigorous quality control, and a customer-first approach to deliver components that exceed expectations.

10000+ Delivered

100+ Employees

18+ years of work

1000 ㎡

To provide innovative, precision-engineered components through state-of-the-art CNC technology while maintaining the highest standards of quality, sustainability, and customer satisfaction.

Integrity: Transparent and ethical practices in every interaction. Quality: Uncompromising standards from design to delivery. Innovation: Embracing technology to solve complex challenges

To become a global benchmark in CNC machining by continuously advancing our capabilities, fostering innovation, and empowering industries with reliable, cost-effective manufacturing solutions

Custom CNC-machined components with tight tolerances, ideal for automotive, aerospace, and industrial applications.

Complex geometries achieved through advanced 3-axis and 5-axis milling for prototypes and bulk production.

Durable, high-strength parts manufactured through cold forging for enhanced structural integrity.

Precision cylindrical parts produced using CNC lathes, perfect for shafts, fittings, and connectors.

High-volume production of stamped metal components with consistent accuracy for electronics and appliances.

High-quality sand casting and investment casting solutions for intricate designs in ferrous and non-ferrous metals.

~

~

~

~

The maintenance of a desired level of quality in a service or product,every stage of the process of delivery or production.

Customer Satisfaction is defined as a measurement that determines how happy customers are with a company's products.

Owing to our sound infrastructure, we can able produce products in bulk quantities and cater to the demands of numerous customers worldwide.

We are one of the leading players in this domain and have implemented innovative business strategies and modern techniques for our business.

Copywrite © 2023 Shree Umiya Enterprise

Managed By Adjoint Infocom Private Limited